Vertical Shaft Impactor VSI Crushers Impact Crushers

The second variation called vertical shaft autogenous (VSA) crushing, where rock is fed intoVertical Shaft Impactor (VSI CRUSHER) is unique due to its crushing process Whereas most other types of crusher use metallic parts to crush rock, and the rock fed into the machine to crush itself This autogenous crushing processVertical Shaft Impactor VSI Crusher – Conmix Crusher

VSI Crusher Vertical Shaft Impactor Metallurgist

06/03/2019· VSI Crusher Vertical Shaft Impactor In a vertical shaft impact crusher, the aggregate feed is introduced into a shoe or pump spinning on aExtremely modular, VSI and GS series crushers’ layouts can be in the same frame and changed without major modifications from a rockonrock rotor to a rockoniron rotor They feature many technical benefits such as the taperedVertical Shaft Impact Crusher AF Minerals Equipment

VSI Crushers REMco

REMco Vertical Shaft Impactors are typically used in the third or fourth stage of crushing circuits Feed rates are from 15 to 1500 TPH Machine drive powers range from 50hp to 1500hp and feed sizes can be from 4” (100 mm) to 1/8"14/03/2017· VSI (Vertical Shaft Impactor) Cone crusher is a primary crusher, used in mining or Ore processing It reduces large aggregates to smaller aggregate VSI means, 'Vertical Shaft Impactor' In which shaft and crushingCone Crusher vs VSI (Vertical Shaft Impactor)

Vertical Shaft Impactors Astec

The efficient and versatile design of the Astec vertical shaft impactors (VSI) delivers highly consistent end products for jobs that demand precision Astec VSI crushers are available in both stationary and portable configurations and produce up to 500 tons per hour With the ability to run in standard, semiautogenous and fully autogenousNesans CF Series Vertical Shaft Impact crushers combine robust design features and high performance with low operating and maintenance costs Most noteworthy of CF Series VSI is that they feature Rock on Rock CrushingVSI Crusher Nesans Mining and Automation Private

Vertical Shaft Impact Crusher Get A Superior VSI Crusher

Vertical shaft impact crusher is also called the sand making machine That is because it can provide the highquality sand or aggregate to the highway, highspeed rail, construction, municipal administration construction, water and electricity dam construction So it is the first choice in sand making and stone shaping fieldsVSI (verticle shaft impact) crushers use a different approach involving a high speed rotor with wear resistant tips and a crushing chamber designed to throw the rock against The VSI crushers utilize velocity rather than surface forceVSI Crushers PECO Sales & Rental

Impact Crushers (HSI and VSI) Sandrock Mining

Common types of Impact Crushers are Horizontal Shaft Impactor (HSI) and Vertical Shaft Impactor (VSI) While the ultimate design of each type of impactor is to crush rock, their methodologies differ Raw materials:The new Patented Tubular Rotor provides many benefits over the standard shoe and anvil designs as well as rockshelf applications The easily replaceable and indexable rotor tubes, cut your total operating cost and maintenance time in half, making VSlam the easiest VSI crusher to maintain and one of the best impact crushers on the marketVertical Shaft Impactors VSI Crushers Stedman Machine

Aftermarket Vertical Shaft Impactor Parts I Mining Wear Parts

A Vertical Shaft Impactor (VSI) operates using a spinning rotor mounted to a vertical axis shaft The rotational speed of the rotor (into which rock is fed vertically) in conjunction with the machine configuration (Rock on Rock, Rock on Steel, or Steel on Steel – also known as Hammer & Anvil) determines the finished product particle size1 天前· The study provides an indepth examination of global Vertical Shaft Impact (VSI) Crushers market growth in terms of revenue and volume in a variety of global regions during the forecastedVertical Shaft Impact (VSI) Crushers Market 2022 Industry Size

Global Vertical Shaft Impact (VSI) Crushers Market Size and

09/11/2022· Common types of Impact Crushers are Horizontal Shaft Impactor (HSI) and Vertical Shaft Impactor (VSI) While the ultimate design of each type of impactor is to crush rock, their methodologies differVertical Shaft Impact Crusher VSI For Sale General Machinery Vertical Shaft Impact Crusher Vbelt drive; designed to convert between rock on rock to rock on steel crushing Upgraded to Canica Model 85 parts – $39,000 Olivehurst, CA, USA Click to Contact Seller Used 2008 BARMAC B7150 USED Manufacturer: minevik;Used vertical shaft impact crusher Machinio

VSI Crushers AGGRETEK Vertical Shaft Impactors

Vertical Shaft Impact (VSI) crushers are designed to be used in secondary, tertiary or quaternary stage crushing These crushers are suitable for a wide range of applications including the production of high quality manufactured sand, well formed aggregates and industrial mineralsThe VSI series vertical impact crushers has two types: rockonrock and rockoniron Rockon rock is to process abrasive material and rockon –iron is to process normal material The production of rockoniron is 1020% higher than rockonrockVSI SERIES VERTICAL SHAFT IMPACT CRUSHER

Stationary VSI impact crushers, Sandvik VSI Crusher

Sandvik Vertical Shaft Impact (VSI) Crushers Throughout our VSI crusher range, we have put the time into what needs to be focused on and what will give you maximum performance when using them This process ensures we canVSI (verticle shaft impact) crushers use a different approach involving a high speed rotor with wear resistant tips and a crushing chamber designed to throw the rock against The VSI crushers utilize velocity rather than surface forceVSI Crushers PECO Sales & Rental

Vertical Shaft Impactor Crusher Manufacturer | Propel

The high velocity impact crusher in Propel VSI enhances the shape of the aggregates and improves the surface structure It is suitable for all types of materials Propel Vertical Shaft Impactor produces shapes as per the Ministry of Road Transport & Highways (MORTH) standards Impact Cartridge Options RockonRock:Common types of Impact Crushers are Horizontal Shaft Impactor (HSI) and Vertical Shaft Impactor (VSI) While the ultimate design of each type of impactor is to crush rock, their methodologies differ Raw materials:Impact Crushers (HSI and VSI) Sandrock Mining

VSI Vertical Shaft Impact Crusher: Usage and Application

10/08/2021· Usage and Application: The vertical shaft impact crusher is advanced and highefficiency equipment It is the latest researched results basing on Germany technology The machine is professional in producing qualified sand and stone for highway, highspeed railway, high building, city project, hydropower dam constructions, and concrete mixing14/03/2017· Cone crusher is a primary crusher, used in mining or Ore processing It reduces large aggregates to smaller aggregate VSI means, 'Vertical Shaft Impactor' In which shaft and crushing chamber are in aCone Crusher vs VSI (Vertical Shaft Impactor)

Vertical Shaft Impact (VSI) Crushers Market 2022 Industry Size

1 天前· The study provides an indepth examination of global Vertical Shaft Impact (VSI) Crushers market growth in terms of revenue and volume in a variety of global regions during the forecasted09/11/2022· Common types of Impact Crushers are Horizontal Shaft Impactor (HSI) and Vertical Shaft Impactor (VSI) While the ultimate design of each type of impactor is to crush rock, their methodologies differGlobal Vertical Shaft Impact (VSI) Crushers Market Size and

[fxp:title]

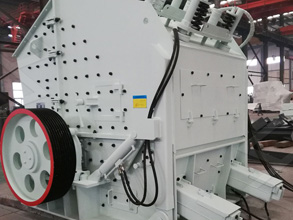

a vsi is a vertical shaft impactor a rock crusher